NEW GREENLIFETIRE MODELS

The Greenlifetire GLT300x25 and GLT250x25 seed press wheels have a specially designed polyurethane tyre with a V-shaped tip that adapts exactly to the shape of the furrow, so as to penetrate deeper, push the seed in and accelerate germination.

NEW GREENLIFETIRE MODELS

The new GLT400x65 gauge wheels in both spoked and full rim versions are the alternative to the traditional GLT400x115, ideal for the latest generation of compact seeders.

AGRITECHNICA 2025 HANNOVER

Mecaplast will be present as an exhibitor at Agritechnica from 9 to 15 November 2025 in Hanover. Visit us at our Stand B70 in Hall 12

Mecaplast

The company

Designand construction of moulds for plastic moulding, injection moulding of plastic articles. For more than 45 years between moulds and moulding Since 1976 the Conti Afro, individual company, has been designing and building moulds for plastic injection moulding. A few years later the first injection moulding machine was installed. In 1999 Conti Afro’s sons took on the activity and the company changed its name to Mecaplast Since 2001 we have been a certified company in conformity to the quality system ISO 9001.

Mecaplast

Our products

GREENLIFETIRE

100% Reciclable tire, GreenLifeTire introduces an important innovation in the agricultural field

Read moreConstruction of large infrastructures

We produce high quality products for the construction of large infrastructures

Read moreCustomization

Customised products to customer's design

Our services

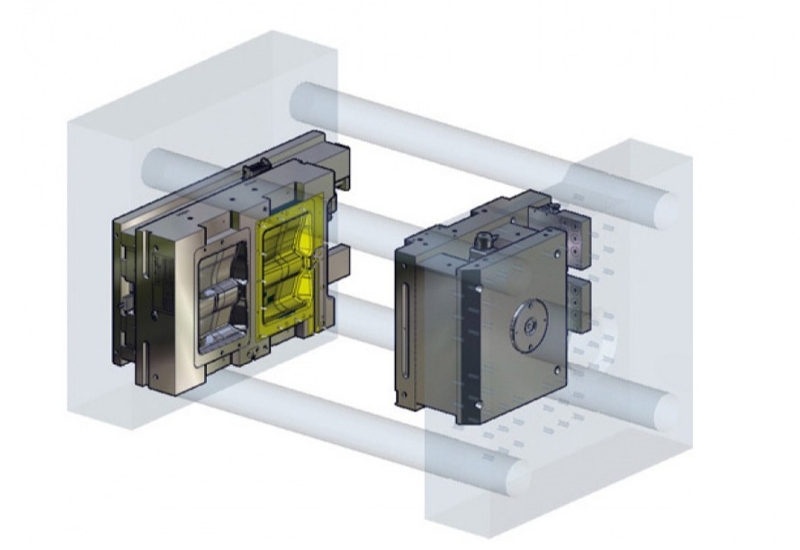

Design and construction of moulds for plastic moulding

They are the three steps for the realization of a new product or an update, which require, for an optimal result, two main supports...

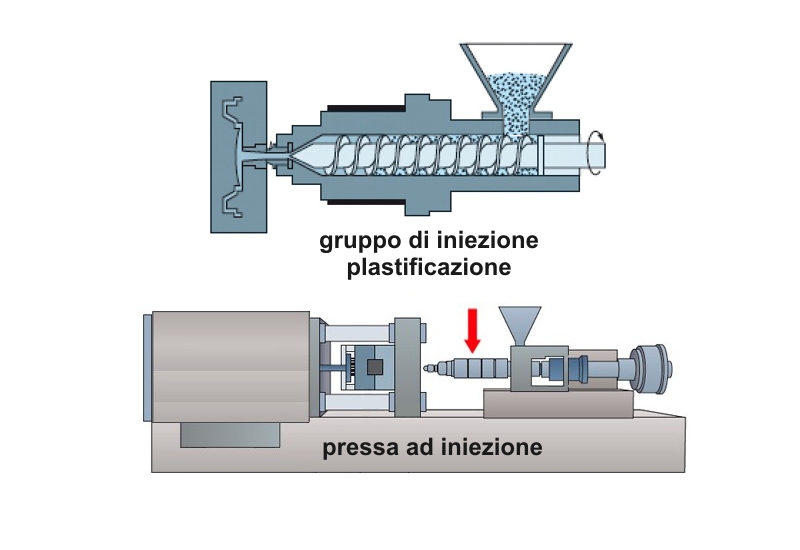

Injection moulding of plastic items

The production department is composed of 10 injection moulding presses with a range from 60 to 380 tonnes of clamping force....

Post-moulding and Workshop Services

The internal workshop enables us to build small moulds and carry out immediate maintenance interventions on the moulds. We have a consolidated collaboration ...

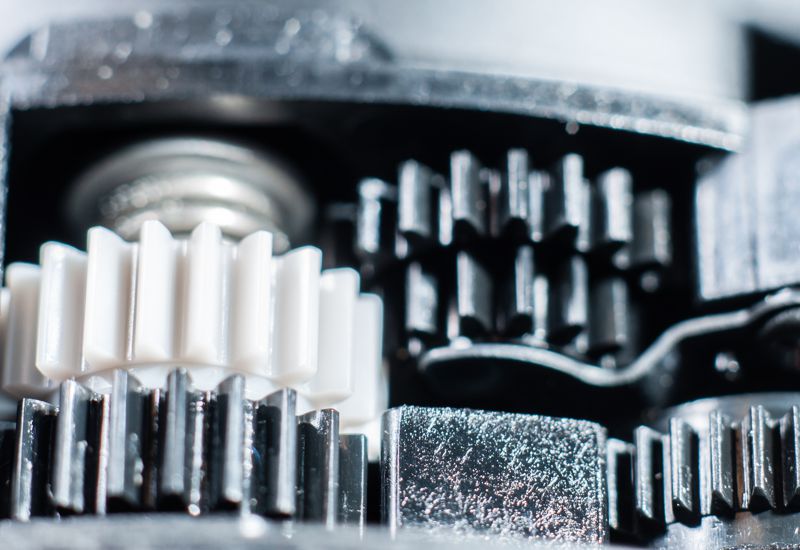

Metal Replacement

Innovating products in order to improve their mechanical and functional characteristics and optimise ther production costs, which is possible by applying high-performance polymers, through targeted projects and processes.

Progetto di promozione di Mecaplast SAS all’estero con particolare riferimento a Germania e Francia

Titolo progetto: Progetto di promozione di Mecaplast SAS all’estero con particolare riferimento a Germania e Francia Descrizione progetto: Il progetto ha riguardato la partecipazione all’edizione 2023 della Fiera Agritechnica che si è svolta ad Hannover (Germania) dal 12 al 18 Novembre 2023. Si tratta della fiera più grande al mondo sull’agricoltura ed il giardinaggio con espositori e visitatori provenienti da tutto il mondo, principalmente da Germania, Francia, Spagna Turchia e Cina. Risultati ed obiettivi: L'obbiettivo primario è incrementare il commercio internazionale e l'aumento della quota di Export verso i paesi target attraverso il raggiungimento dei seguenti risultati:

Il Progetto è stato realizzato grazie al sostegno finanziario ricevuto dall’Unione Europea.

Newsletter

Do you want to be always informed about news?